Company Strength

-The company has been in existence for more than 10 years

-more than 700 employees

-Half a million treadmills

-300,000 exercise bikes

-More than 100 countries

-The total construction area is 67000 square meters

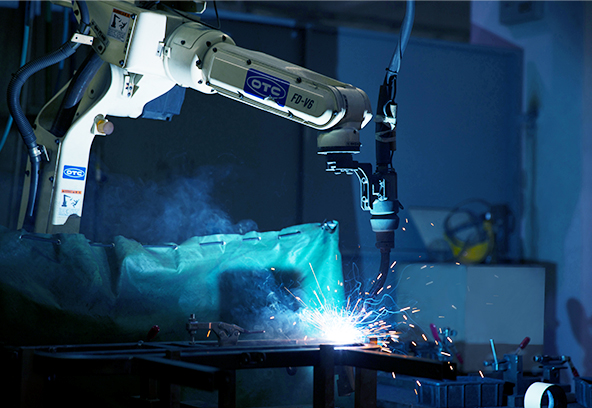

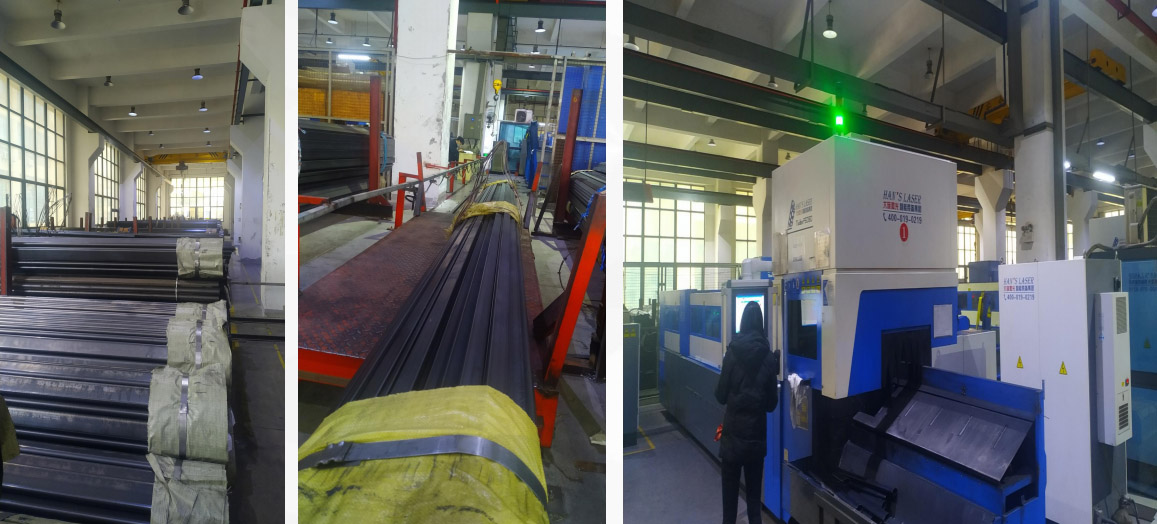

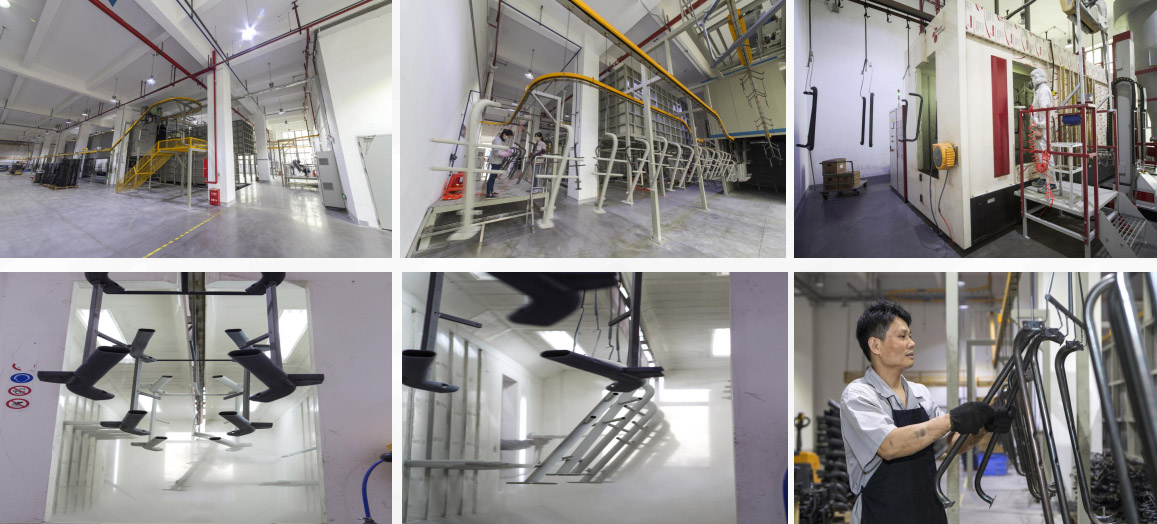

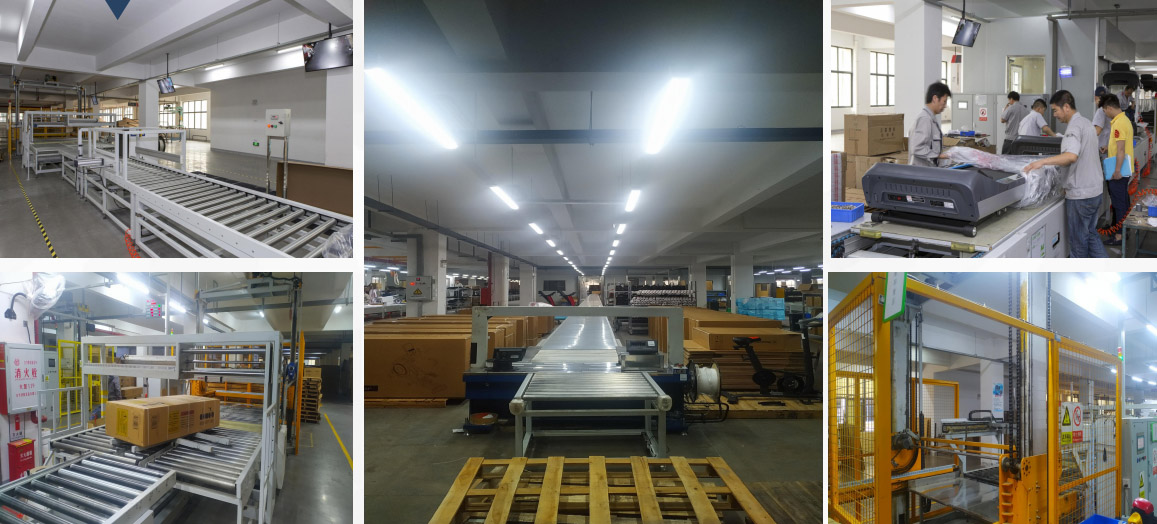

Production Equipment

Automatic machines are very important as a modernization factory. Mydo sports has auto laser cutting machines, auto welding robot, auto painting line, auto assembly line and auto packing line. All the production strictly follow ISO quality management system make sure each and every treadmill and elliptical trainer could be produced as standard quality item.

OEM / ODM Service

We offer ODM and OEM services to meet different clients’ requirements.

If you need OEM service of printing your own brand on each piece of Treadmills or bikes, we can do that, too.

Or if you need ODM service in process technology, material, design, etc, you can send your requirement, the R & D team will try their bests to work on that.

Equipment and Process

Laser cutting machine

Laser cutting machine

fully automatic welding machine

fully automatic welding machine

fully automatic coating line

fully automatic coating line

Assembly line for treadmills

Automated packaging machine

Pipe warehouse and material transportation, laser cutting

Laser cutting - punching - bending - welding

Automatic painting and painting

production line

Production process quality control

Automatic packaging and sealing

delivery

Material placement

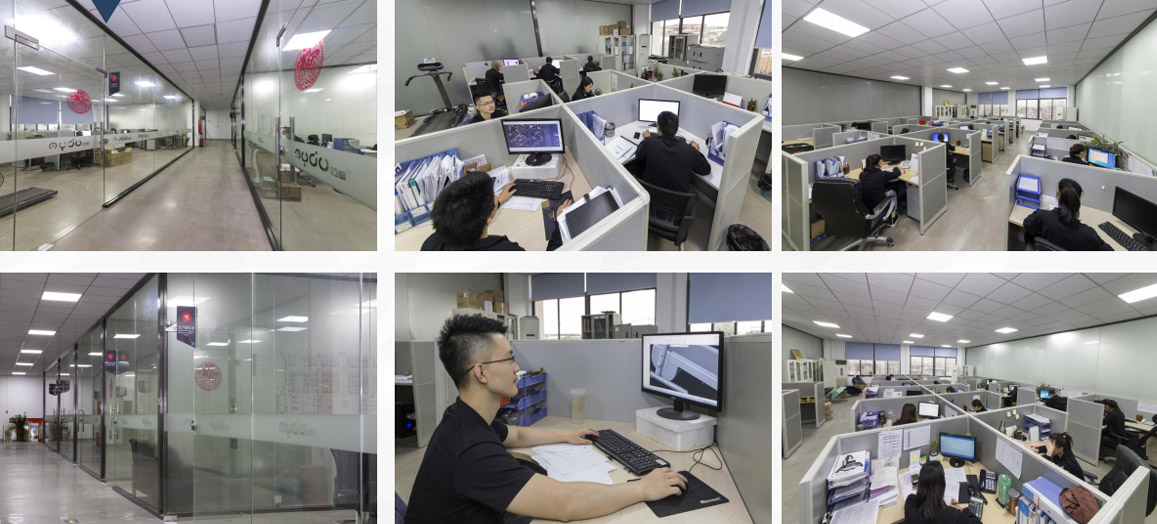

Office environment

Testing Laboratory

IQC ( Incoming Quality Control)

- For all incoming material, we will do IQC to ensure that the raw materials meet our standards.

- IQC frequency follow AQL standard.

OQC ( Outgoing Quality Control)

- Before loading, we will check container outlook, container number and product name to make sure right loading.

Laboratory

- We have our own laboratory and our lab was authorized as qualified testing location by SGS.

PQC( Production Quality Control)

- Mass production in process control:

A. All products will go through empty loading test for 20 mins, then go through earth test, electrical leakage test, HIPOT test and insulation test.

B. To make sure customer can assemble, all products will be fully assembled first, then disassemble to packing.

- Mass production finished product control:

A. We will do the first article inspection, and then proceed mass production.

B. We will do sampling inspection to control the quality. Sampling frequency 2% of order quantity. And our quality personnel will run on the treadmill to test it is loading.